“Industrial” or “rugged” in the context of electronic devices refers to equipment that is specifically designed to withstand harsh environmental conditions and heavy-duty use in industrial settings. These devices are built to be durable, resistant to environmental factors, and capable of performing reliably in challenging conditions. Here are key features and applications of industrial/rugged devices:

Key Features of Industrial/Rugged Devices:

- Durability:

- Industrial devices are built with robust materials and construction to withstand physical impacts, vibrations, and rough handling.

- Rugged Design:

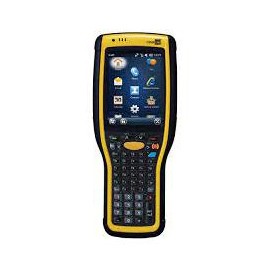

- Rugged devices often have a reinforced and sealed design, providing protection against dust, water, and other environmental elements. They may comply with industry-specific standards for ruggedness.

- Shock and Vibration Resistance:

- Industrial devices are designed to resist shocks and vibrations commonly encountered in industrial environments, such as manufacturing floors or construction sites.

- Wide Operating Temperature Range:

- These devices can operate within a wide temperature range, making them suitable for environments with extreme temperatures, whether hot or cold.

- Sealed Ports and Connectors:

- Ports and connectors on rugged devices are often sealed to prevent the ingress of dust, water, or other contaminants.

- Sunlight Readability:

- Displays on rugged devices may incorporate technology for improved visibility in bright sunlight, ensuring readability in outdoor environments.

- Long Battery Life:

- Rugged devices may feature optimized power management systems to provide extended battery life, crucial for field use where charging may be limited.

- Chemical Resistance:

- Some industrial devices are designed to resist exposure to chemicals commonly found in industrial settings, preventing damage and corrosion.

- Customization and Modular Design:

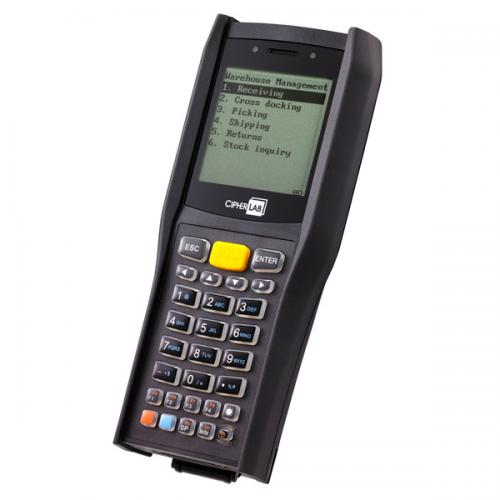

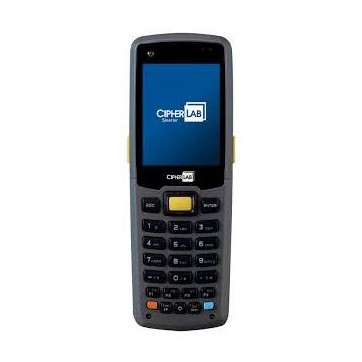

- Industrial devices often have a modular design that allows for customization based on specific industry needs. Modules, such as barcode scanners or RFID readers, can be added or replaced.

- EMI/RFI Shielding:

- Electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding is implemented to ensure reliable operation in environments with high levels of electromagnetic noise.

Applications of Industrial/Rugged Devices:

- Manufacturing:

- Rugged devices are used on manufacturing floors for tasks such as inventory management, quality control, and process monitoring.

- Field Service and Maintenance:

- Field technicians use rugged devices for tasks like equipment diagnostics, maintenance, and repair in industries such as utilities, telecommunications, and energy.

- Construction:

- Rugged tablets and handhelds are employed on construction sites for project management, documentation, and communication.

- Logistics and Warehousing:

- In logistics and warehouses, rugged devices are used for inventory tracking, order picking, and shipping/receiving operations.

- Transportation and Fleet Management:

- Rugged devices are integrated into vehicles for tasks such as navigation, route optimization, and communication in transportation and fleet management.

- Agriculture:

- In agricultural settings, rugged devices assist with tasks like precision farming, crop monitoring, and equipment control.

- Military and Defense:

- Rugged devices are used in military applications for field communications, data collection, and mission-critical operations.

- Mining:

- In mining operations, rugged devices are employed for tracking resources, monitoring equipment, and ensuring worker safety.

- Oil and Gas:

- Rugged devices are used in oil and gas exploration and production for data collection, asset tracking, and monitoring.

- Healthcare:

- In healthcare environments, rugged tablets or computers may be used for tasks like patient data collection, bedside care, and mobile health applications.

Industrial or rugged devices play a vital role in enhancing efficiency and reliability in demanding environments where standard consumer-grade devices might not withstand the conditions. Their durability and specialized features make them well-suited for a wide range of industrial applications.