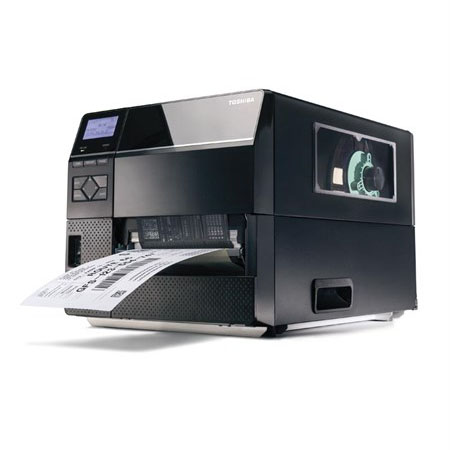

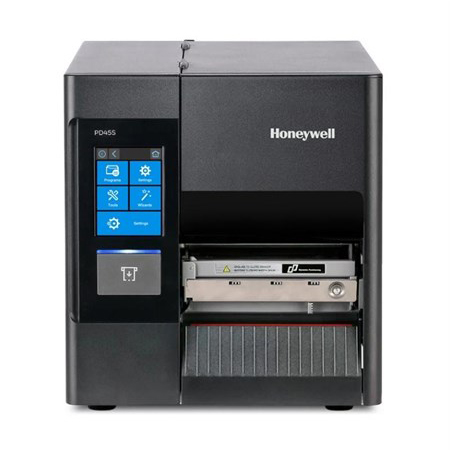

Industrial label printers are robust, heavy-duty devices designed for high-volume and demanding label printing applications in industrial environments. These printers are commonly used in manufacturing, logistics, and other industries where durable and high-quality labels are essential. Here are key aspects associated with industrial label printers:

- Printing Technologies:

- Thermal Transfer Printing: Utilizes a thermal print head to transfer ink from a ribbon onto the label material. Ideal for applications requiring durable and long-lasting labels.

- Direct Thermal Printing: Uses heat-sensitive paper to create monochrome labels. Suited for applications where labels won’t be exposed to heat or sunlight for extended periods.

- Print Resolution:

- Measured in dots per inch (dpi), print resolution determines the sharpness and clarity of labels. Industrial label printers often feature high dpi values for producing detailed and precise prints.

- Label Material Compatibility:

- Industrial label printers support a wide range of label materials, including synthetic materials, polyester, polypropylene, and heat-resistant labels. This versatility allows for customization based on specific application requirements.

- Label Size and Width:

- Industrial label printers can accommodate larger label sizes and widths, making them suitable for a variety of labeling needs. This capability is crucial for applications such as shipping labels and product identification.

- Print Speed:

- Industrial label printers are known for their high print speeds, measured in inches per second (IPS) or labels per minute (LPM). The fast printing capabilities contribute to increased productivity in industrial settings.

- Connectivity:

- Industrial label printers offer diverse connectivity options, including USB, Ethernet, serial, and wireless interfaces. This allows for seamless integration into industrial networks and facilitates communication with other devices.

- Durability and Construction:

- Built with durable materials, industrial label printers are designed to withstand harsh industrial environments. They often have metal casings, robust components, and protection against dust, moisture, and vibrations.

- Label Roll Capacity:

- Industrial label printers typically have large label roll capacities, reducing the frequency of label roll changes. This feature is beneficial for continuous and uninterrupted printing in high-volume applications.

- Barcoding and Label Design Software:

- Industrial label printers are compatible with advanced barcoding and label design software. These tools enable users to create complex labels, barcodes, and variable data elements for diverse industrial applications.

- User-Friendly Interface:

- While designed for industrial use, these printers often feature user-friendly interfaces with LCD screens, touch panels, and intuitive controls. This simplifies setup, operation, and troubleshooting.

- Media Sensors:

- Advanced media sensors in industrial label printers detect gaps, notches, or reflective marks on the label material, ensuring accurate and consistent label placement and printing.

- Integration with Industrial Systems:

- Industrial label printers are designed for seamless integration with industrial automation and control systems. They often support standard industrial communication protocols for enhanced connectivity.

- Ruggedized and Mobile Options:

- Some industrial label printers come in ruggedized versions for extreme conditions or mobile options for on-the-go printing in industrial settings.

- Environmental Considerations:

- Industrial label printers may incorporate energy-saving features and comply with environmental standards, contributing to sustainability efforts.